Precision at its Finest: Elevate Your Lab Experiments with Global Lab Supplies

Pulverizing Bowls

Pulverizing bowl: also called pulverising mill grinding bowl, pulverizer mill bowl. It is a grinder that grinds coarse material into fine powder. When working, put the grinding bowl into the laboratory sample pulverizer or vibration grinder card slot. The motor drives the grinding bowl to eccentrically vibrate. After 2-6 minutes of work, the material can reach 80-300 mesh for testing.

Pulverizing Bowls

Request a Call Back

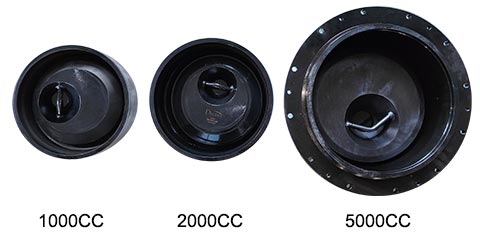

Pulverizing bowls available in various materials and capacities

Pulverizing bowl: also called pulverising mill grinding bowl, pulverizer mill bowl. It is a grinder that grinds coarse material into fine powder.

When working, put the grinding bowl into the laboratory sample pulverizer or vibration grinder card slot. The motor drives the grinding bowl to eccentrically vibrate. After 2-6 minutes of work, the material can reach 80-300 mesh for testing.

The material of the ring and puck bowl includes carbon steel, high manganese steel, alloy, tungsten carbide, and chrome steel.

The series of grinding bowls of GLS has good wear resistance and impact resistance. A unique range of bowls from 40 to 5000g nominal capacity. The “bowl and disc” style grinding head forms the core of GLS’s extensive bowl range.

We delivers this high-capacity, high-production bowl to the sample preparation market over 10 years. Today it is still the preferred bowl of choice in most of the world’s leading commercial testing laboratories.

These bowls are of through-hardened steel construction for optimum life. They are available in 640, 800, 1600, and 3500g nominal capacities. GLS “ring and puck” style bowls are available in the smaller 50, 100, 125, 300 & 400cc nominal capacities. These too are of through-hardened steel construction, with tungsten carbide available in the 125cc size. This innovative crushing and grinding configuration provide rapid preparation of large samples up to 5000g in nominal capacity.

Application range: metals with certain hardness, non-metals (coal, rock, coke, ore, granular materials), and other minerals.

[ TECHNICAL PARAMETERS ]

| Model | DB2000 | DB1000 | DB800 | DB300/400 |

| Max. Capacity | 300-1600g | 150-800g | 120-640g | 75-320g |

| Weight | 27.5kg | 20kg | 14kg | 13kg |

| Bowl Outer Dia. | 27.5cm | 25.5cm | 22.7cm | 21.8cm |

| Height | 12.5cm | 9.5cm | 9cm | 7cm |

| Parts | Lid & seal, disc and bowl | Lid & seal, bowl, roller, inner ring | ||

| Material | Standard steel, Chrome steel, Carbon steel, High manganese steel, Alloy, Tungsten carbide | |||

Related Products

GLS has various shapes of horseshoe-shaped furnaces, furnace tubes, electric furnace tile plates, rails, large-span muffle furnaces, etc. Used in various heat treatment furnaces, such as muffle furnaces, enamel sintering furnaces, diffusion furnaces, slats of various kilns, flameproof materials, etc.

Safety goggles can provide special eye protection for specific work and environments. Safety goggles are your ideal choice when you need to minimize the risk of liquid splash, corrosive vapor, air dust and solid particles’ high-speed impact. Safety goggles are mainly divided into three types: anti-solid debris, anti-chemical solution and anti-radiation.

Cupel is a shallow, porous crucible with approximately 96% magnesia. It is especially used to separate gold, silver, and precious metals from lead buckles in the process of Pb-Fire assay. By using high-quality raw materials and scientific formulas, GLS’s fire assay magnesia cupel has a smooth surface, high mechanical strength, and will not crack and pit during high-temperature cupellation.

The series of grinding bowls of Global Lab Supply has good wear resistance and impact resistance. A unique range of bowls from 40 to 5000g nominal capacity. Global Lab Supplies delivers this high-capacity, high production bowl to the sample preparation needs.